When it comes to industrial washing machine or commercial washer extractor operations, understanding industrial washing machine capacity is like knowing the engine size of a car—it’s the key to unlocking maximum performance. But how do you calculate capacity, and why does it matter? In this guide, we’ll unravel the mysteries of industrial washing machine capacities and show you how to make every load count.

Table of Contents

- 1. Understanding the Basics of Industrial Washing Machines

- 2. Types of Industrial Washing Machines and Their Capacities

- 3. Factors Influencing Industrial Washing Machine Capacity Calculations

- 4. How to Calculate Industrial Washing Machine Capacity

- 5. Choosing the Right Washing Machine Capacity

- 6. Tips for Optimizing Industrial Washing Machine Capacity Usage

- 7. Real-World Applications of Industrial Washing Machine Capacity Calculations

- 8. Conclusion: Maximizing Output with Accurate Industrial Washing Machine Capacity Calculations

- 9. FAQs About Industrial Washing Machine Capacity

1. Understanding the Basics of Industrial Washing Machines

1.1. What is Industrial Washing Machine Capacity?

Capacity refers to the maximum weight of textiles a washing machine can handle per load, typically measured in kilograms or pounds. Unlike domestic machines, industrial washers are designed to manage larger, heavier loads, making them ideal for industries like hospitality, healthcare, and manufacturing.

1.2. Why is Capacity Calculation Important?

Calculating capacity isn’t just a numbers game—it’s the backbone of efficient operations. Here’s why:

1.2.1 Impact on Efficiency and Productivity

Using machines at optimal capacity ensures shorter wash cycles and reduces wear and tear. When every minute counts, especially in high-volume industries, getting this right can save hours.

1.2.2 Avoiding Overloading and Underloading

Overloading can strain the motor and compromise wash quality, while underloading wastes water, detergent, and energy. Striking the right balance means better results and lower costs.

2. Types of Industrial Washing Machines and Their Capacities

Not all industrial washers are created equal. Each type comes with specific capacity ranges to suit different needs.

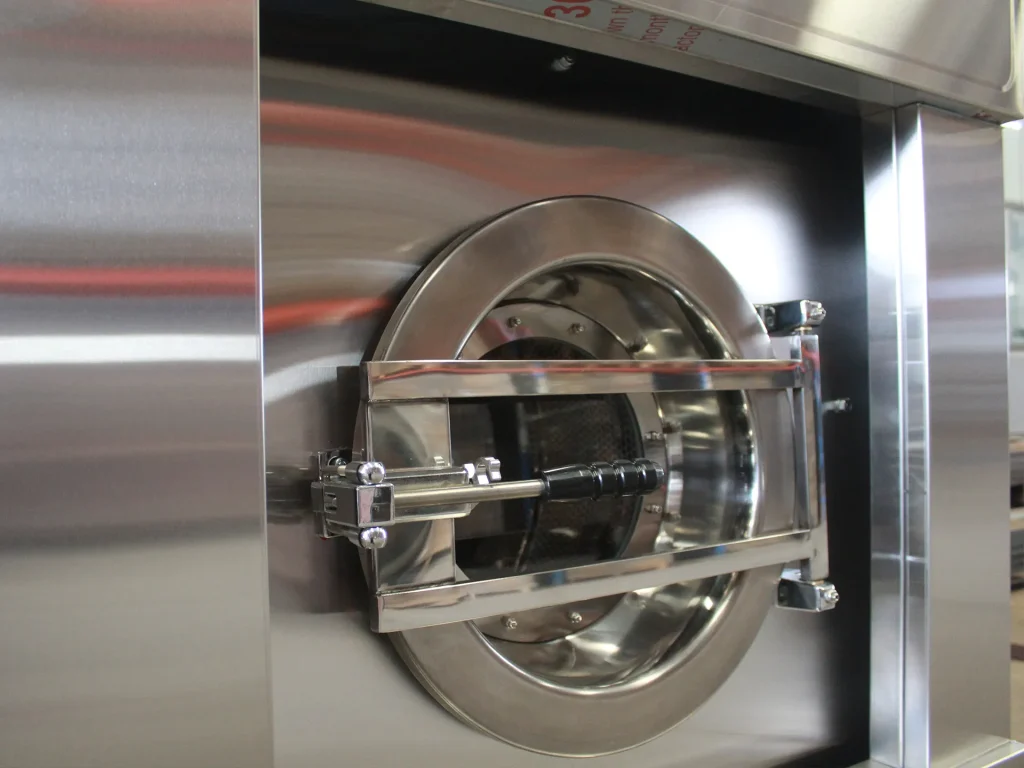

2.1. Front-Load Machines

These are versatile, handling loads of up to 50 kg. They’re great for small to medium-sized facilities.

2.2. Tunnel Washers

Built for heavy-duty tasks, tunnel washers can process up to 600 kg per hour. Think of them as the conveyor belts of the laundry world.

2.3. Barrier Washers

Designed for hygiene-critical environments, barrier washers typically range from 20 to 100 kg in capacity, ideal for hospitals and laboratories.

2.4. Batch Washers

Batch washers are your go-to for handling similar fabrics in bulk, with capacities varying widely from 50 to 400 kg.

3. Factors Influencing Industrial Washing Machine Capacity Calculations

Several variables affect how much your machine can handle.

3.1. Type of Fabric Being Washed

Heavier fabrics like towels and uniforms absorb more water, reducing capacity compared to lighter fabrics such as bedsheets.

3.2. Load Composition and Distribution

Uneven loads can throw machines off balance, so evenly distributing items ensures maximum capacity utilization.

3.3. Machine Design and Drum Size

A larger drum allows for more textiles per load, but the design also dictates how space is utilized.

3.4. Water Absorption Rates

Fabrics with high absorption rates weigh more when wet, which impacts the effective capacity of your washer.

4. How to Calculate Industrial Washing Machine Capacity

Now that we understand the basics, let’s talk about how to calculate the right industrial washing machine capacity for your needs.

4.1. Estimating laundry load weight

To estimate the weight of your laundry, you can use a kitchen scale or refer to laundry load weight charts.

4.2. Determining laundry load density

You can estimate laundry load density based on the types of laundry you typically wash. For example, towels and blankets are denser than shirts and sheets.

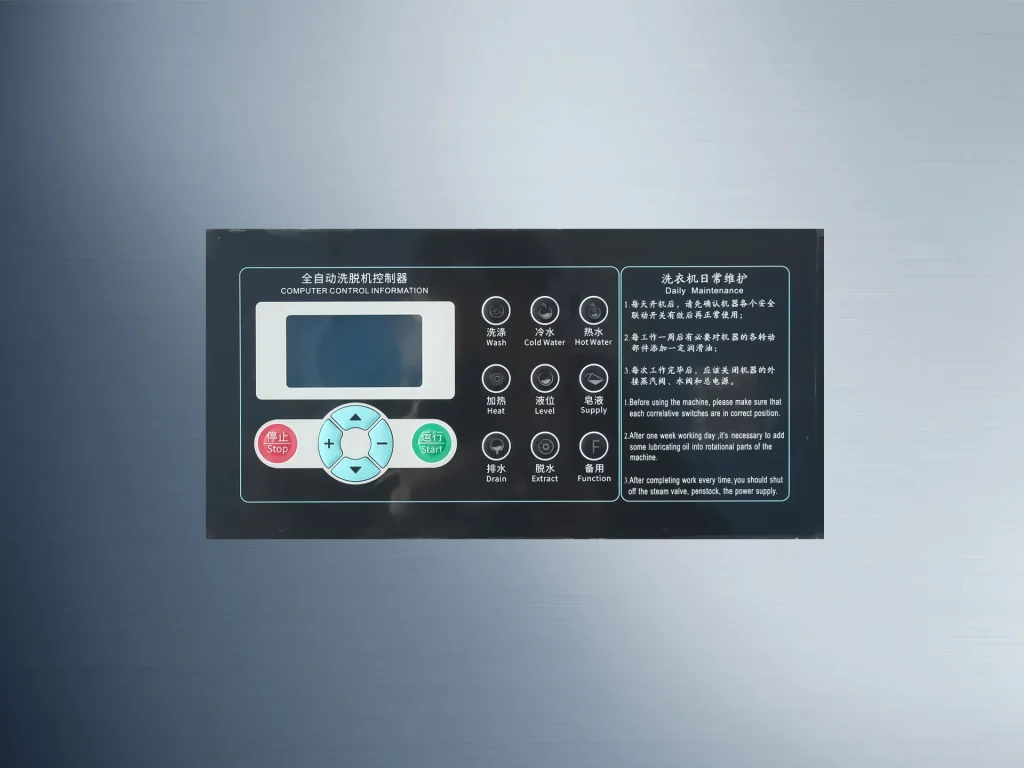

4.3. Using industrial washing machine capacity charts

Many washing machine manufacturers provide industrial washing machine capacity charts that can help you determine the appropriate capacity based on your laundry load weight and density.

4.4. Calculating capacity based on dimensions

If you know the dimensions of your laundry room, you can use online calculators to estimate the maximum capacity of the washing machine you can fit.

4.5. Understanding Load Ratios

Industrial machines often specify load ratios, such as 1:10, which means 1 kg of dry linen requires 10 liters of water. Knowing this helps fine-tune calculations.

4.6. Step-by-Step Calculation Method

- Determine the machine’s drum volume in cubic meters.

- Multiply the volume by the machine’s load ratio.

- Adjust for fabric type and water absorption.

- Here we can refer to a industrial washing machine capacity calculation way by clicking here.

4.7. Common Mistakes to Avoid

- Ignoring the type of fabric in calculations.

- Forgetting to account for water absorption.

- Overestimating capacity by not considering load balancing.

5. Choosing the Right Washing Machine Capacity

Once you’ve calculated your laundry load weight and density, you can start comparing washing machines to find one that meets your needs.

5.1. Considering your specific needs

Think about your business’s specific requirements. Do you need a machine that can handle large, bulky items? Or do you primarily wash smaller, lighter loads?

5.2. Balancing capacity and efficiency

It’s important to balance capacity with efficiency. A larger machine might be more expensive to operate and require more space.

5.2.1. Overloading vs. underloading

Be careful not to overload your washing machine, as this can damage the machine and your laundry. However, underloading can also be inefficient.

5.3. Water consumption and energy efficiency

Look for machines with energy-efficient ratings to save money on your utility bills.

5.4. Installation and maintenance

Consider the space available in your laundry room and the ease of installation. Also, think about the machine’s maintenance requirements.

5.4.1. Space requirements

Make sure you have enough space for the washing machine, including room for loading and unloading.

5.4.2. Regular cleaning and maintenance

Regular cleaning and maintenance are essential to ensure your washing machine operates efficiently and lasts longer.

6. Tips for Optimizing Industrial Washing Machine Capacity Usage

Maximizing efficiency requires more than just correct calculations.

6.1. Best Practices for Load Balancing

Evenly distribute items to prevent strain on the motor and ensure consistent wash quality.

6.2. Regular Maintenance and Monitoring

Keep machines in peak condition with routine maintenance checks. Clean filters and inspect drum seals regularly.

6.3. Energy Efficiency Tips

Use energy-saving cycles and optimize water usage. Small changes here can lead to big savings over time.

7. Real-World Applications of Industrial Washing Machine Capacity Calculations

Capacity calculations aren’t just theoretical—they have real-world benefits.

7.1. Case Study: Hospitality Industry

Hotels rely on precise capacity calculations to handle high volumes of sheets and towels without delays.

7.2. Case Study: Healthcare Sector

Hospitals use barrier washers for critical hygiene, where underloading wastes resources and overloading compromises cleanliness.

7.3. Case Study: Industrial plant laundry

Industrial plants may have unique laundry needs, such as processing specialized workwear or cleaning equipment. Washing machines must be tailored to these specific requirements.

7.4. Hotel laundry

A large hotel with a high occupancy rate will need multiple high-capacity washing machines to handle the volume of laundry generated by guests.

7.5. Hospital laundry

Hospitals have specific requirements for laundry processing, including infection control and compliance with regulatory standards. Washing machines must be selected to meet these requirements.

8. Conclusion: Maximizing Output with Accurate Industrial Washing Machine Capacity Calculations

Accurate capacity calculations are the cornerstone of efficient industrial laundry operations. By understanding the variables and following best practices, you can improve productivity, reduce costs, and extend the life of your equipment. So, what’s stopping you from optimizing your washing machines today?

Ready to take your industrial laundry to the next level? Contact us to learn more about optimizing your operations and make better use of your industrial washing machine capacity!

9. FAQs About Industrial Washing Machine Capacity

How do I know if my washing machine is overloaded?

Look for signs like prolonged wash cycles, excessive vibration, or poor cleaning results.

What’s the best way to measure drum volume?

Measure the drum’s diameter and depth, then use the formula: Volume = π × radius² × depth.

Can I use the same capacity for all fabric types?

No, capacity varies depending on fabric weight and water absorption rates.

Why is load distribution important?

Uneven loads can cause imbalances, leading to mechanical issues and uneven cleaning.

How often should I service my industrial washer?

Regular servicing every 3-6 months is ideal to ensure optimal performance.

Can I overload a washing machine without damaging it?

Overloading a washing machine can put strain on the machine’s components and lead to damage. It’s important to follow the manufacturer’s guidelines for maximum load capacity.

How often should I clean my industrial washing machine?

Regular cleaning is essential for maintaining the performance and longevity of your washing machines. Consult the manufacturer’s recommendations for cleaning schedules.

What is the difference between a top-loading and a front-loading washing machine?

Top-loading machines have a lid at the top, while front-loading machines have a door at the front. Front-loading machines are generally more energy-efficient and have higher spin speeds.

How can I reduce water consumption in my industrial laundry?

There are several ways to reduce water consumption, such as using high-efficiency washing machines, optimizing water temperature settings, and reducing water usage for rinsing.

What is the ideal washing machine capacity for a small business?

The ideal capacity will depend on the specific needs of your business, including the volume of laundry generated and the types of fabrics being washed. It’s important to carefully consider your requirements before making a decision.

Here are some other articles that we think might interest you:

Environmental Impact of Industrial Laundry