Laundry plays an essential role in industries like hospitality, healthcare, and fitness. Choosing between a wash extractor vs traditional washing machine is a significant decision. While both are designed to clean fabrics, they serve vastly different purposes based on scale, efficiency, and user needs. In this article, we’ll dive deep into their features, differences, and suitability for various industries, helping you decide which machine suits your business better. Whether you’re running a small operation or managing large-scale laundry needs, understanding these differences can save you time, money, and resources.

(Learn more about industrial laundry solutions at Spin Washing.)

1. What is a Wash Extractor?

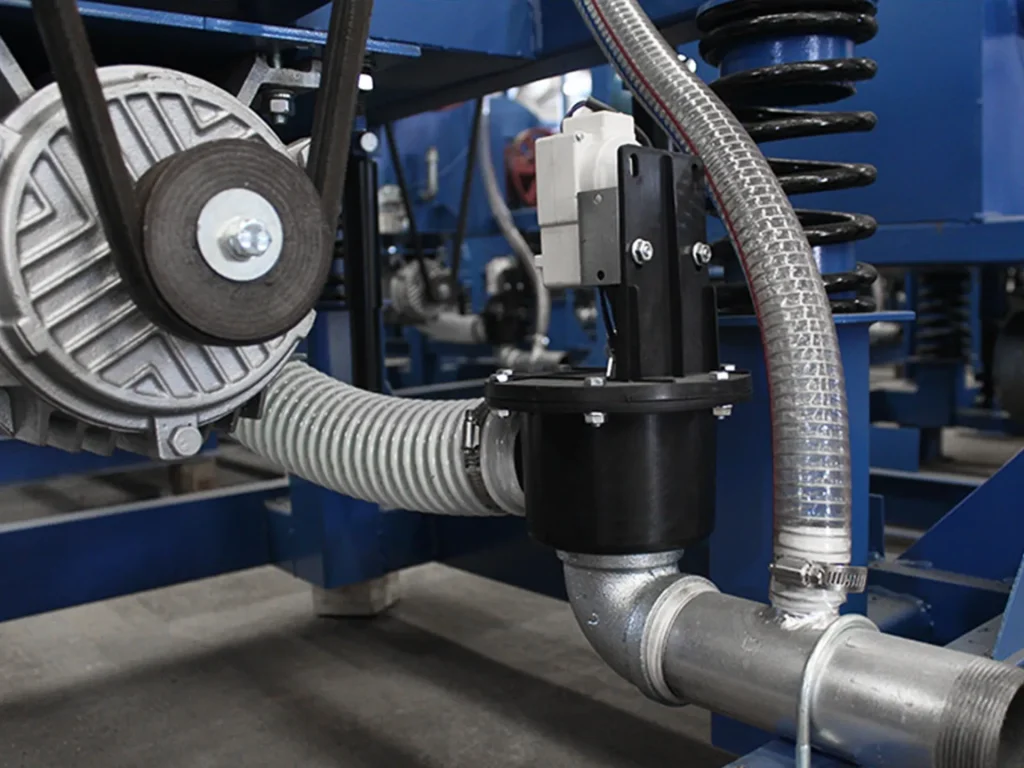

Wash extractors are industrial-grade laundry machines built for high-capacity operations. They combine washing and extraction functions, making them a versatile solution for businesses that require bulk cleaning. These machines are engineered to be efficient, powerful, and durable, meeting the demands of industries like hotels, hospitals, and large-scale laundromats. Wash extractors are more than just machines—they’re workhorses that redefine what efficiency looks like in the laundry sector.

Definition and Overview

Wash extractors integrate washing and high-speed spinning to remove excess water from fabrics. Unlike traditional machines, they’re designed to handle heavy loads while maintaining exceptional cleaning standards. With advanced programming options, they can cater to diverse fabric types and cleaning requirements, making them an all-in-one solution for industrial needs.

Key Features of a Wash Extractor

- High-Speed Extraction: Removes up to 90% of water, drastically reducing drying times.

- Large Capacity: Can handle heavy and bulk loads, perfect for large-scale operations.

- Energy Efficiency: Uses optimized cycles to minimize water and energy consumption.

- Programmable Settings: Tailored cycles for delicate fabrics, heavy linens, or mixed loads.

2. What is a Traditional Washing Machine?

Traditional washing machines are household staples, designed primarily for residential or small-scale commercial use. They’re known for their simplicity, affordability, and ease of operation. While they’re excellent for personal use, traditional machines often fall short in meeting industrial laundry demands due to limited capacity and longer cycle times.

Definition and Overview

A traditional washing machine typically comes in top-load or front-load designs, relying on agitating drums to clean clothes. These machines are ideal for daily household needs but may struggle with consistent performance when dealing with high-frequency, large-scale loads.

Common Features of Traditional Washing Machines

- User-Friendly Controls: Intuitive buttons or dials for quick setup.

- Moderate Capacity: Suitable for small to medium loads.

- Affordable Pricing: Accessible to homes and small businesses on a budget.

- Compact Design: Requires less space compared to industrial machines.

3. Key Differences Between Wash Extractors and Traditional Washing Machines

Both wash extractors and traditional washing machines excel in different areas, but their fundamental differences set them apart. Understanding these distinctions can help businesses choose the right equipment based on their needs.

Performance and Cleaning Efficiency

Wash extractors outperform traditional machines in cleaning heavy stains and maintaining hygiene standards. With powerful extraction cycles, they’re built for thorough cleaning, while traditional machines are more suited for lighter laundry.

Capacity and Load Management

Industrial wash extractors can process up to ten times the load of a traditional washing machine in one cycle. For hotels or hospitals, where bulk cleaning is critical, this capacity is a game-changer.

Energy and Water Efficiency

While traditional machines consume more water and energy per load, wash extractors are designed to operate with minimal resources, reducing overall operational costs. Their efficiency aligns with sustainability goals, especially for businesses aiming to reduce their environmental footprint.

Maintenance and Durability

Wash extractors are engineered for long-term use under rigorous conditions, requiring occasional professional maintenance. Traditional machines, while easier to repair, are less durable and need frequent replacements when used for high-capacity laundry.

4. Advantages of Wash Extractors

Time Savings

Time is money, especially in industries like hospitality. Wash extractors cut down laundry cycles by combining washing and water extraction in one machine. This reduces drying times and speeds up the entire laundry process, helping businesses operate more efficiently.

Enhanced Hygiene and Cleaning Standards

Industries like healthcare and food services demand impeccable hygiene standards. Wash extractors are built with advanced cleaning mechanisms that eliminate bacteria, allergens, and tough stains, ensuring fabrics meet safety and cleanliness standards.

Cost-Effectiveness in the Long Run

Although wash extractors require a higher initial investment, they pay off over time. Their energy efficiency, durability, and reduced maintenance costs make them a more economical choice for businesses handling high laundry volumes.

5. Disadvantages of Wash Extractors

Initial Investment Costs

One of the main drawbacks of wash extractors is their upfront cost. These machines are designed for industrial use and come with a price tag to match. However, for businesses with high laundry demands, this investment is often justified by long-term savings.

Training Requirements

Wash extractors are more complex to operate than traditional washing machines. Staff may need training to understand the machine’s programmable settings and proper maintenance procedures. While this learning curve is manageable, it’s an added consideration for businesses.

6. When to Choose a Traditional Washing Machine

Small-Scale Operations

If your business only handles a few loads of laundry daily, a traditional washing machine may be all you need. Small cafes, boutique inns, or home-based ventures can benefit from their simplicity and affordability.

Budget Considerations

For startups or businesses with limited budgets, traditional washing machines offer a practical solution. Their lower upfront cost and ease of use make them accessible for businesses just starting out.

7. Choosing the Right Solution for Your Needs

Factors to Consider

When deciding between a wash extractor and a traditional washing machine, assess your laundry volume, operational budget, and efficiency goals. Large-scale operations will benefit more from wash extractors, while smaller ventures can stick to traditional machines.

Industry-Specific Recommendations

- Hospitality: Opt for wash extractors to handle bed linens and towels efficiently.

- Healthcare: High hygiene standards make wash extractors the preferred choice.

- Small Businesses: Traditional machines are cost-effective for light use.

8. Conclusion

Deciding between a wash extractor and a traditional washing machine boils down to your business’s specific needs. While wash extractors excel in efficiency, capacity, and hygiene, traditional machines offer simplicity and affordability. By evaluating your laundry requirements and long-term goals, you can make an informed choice that enhances your operations and saves costs.

(Explore premium industrial laundry solutions at Spin Washing or Contact Us for expert advice.)

9. FAQs

What industries benefit most from wash extractors?

Wash extractors are ideal for hospitality, healthcare, and industrial laundries requiring bulk cleaning.

Are wash extractors eco-friendly?

Yes, their energy and water-efficient design reduces resource consumption, making them environmentally friendly.

How often should wash extractors be serviced?

Regular maintenance is recommended every six months to ensure optimal performance and longevity.

Can wash extractors handle delicate fabrics?

Yes, programmable settings allow for customized cycles, ensuring delicate fabrics are cleaned safely.

What is the typical lifespan of a wash extractor?

With proper maintenance, a wash extractor can last 10-15 years, making it a durable choice for industrial use.

Here are some other articles that we think might interest you:

Environmental Impact of Industrial Laundry