Designing an industrial laundry operation is no small task. A good design maximizes space, ensures smooth workflow, and increases productivity, all while keeping safety, energy efficiency, and ergonomics in mind. In this article, we’ll dive into the key elements of industrial laundry design, ensuring your business runs like a well-oiled machine.

Table of Contents

- 1. What is Industrial Laundry Design?

- 2. Understanding Workflow in Industrial Laundry

- 3. Factors to Consider in Industrial Laundry Design

- 4. The Role of Technology in Modern Laundry Layouts

- 5. Common Mistakes in Industrial Laundry Layouts

- 6. Case Studies of Effective Laundry Designs

- 7. Conclusion: Key Takeaways for a Successful Laundry Layout

- 8. FAQs

1. What is Industrial Laundry Design?

Industrial laundry design refers to the strategic planning of spaces, equipment, and workflows to create a highly efficient laundry operation. This encompasses everything from where machines should be placed to how the staff moves throughout the facility. A well-designed laundry space leads to a reduction in wasted time, fewer accidents, and better overall performance.

1.1. Key Elements of a Good Laundry Layout

A good industrial laundry layout includes:

- Space zoning: This involves organizing the space into clearly defined zones for different processes (e.g., sorting, washing, drying, folding).

- Flow management: Ensuring that items move seamlessly from one stage to the next without unnecessary backtracking.

- Equipment placement: Strategically positioning machines to reduce labor costs and increase productivity.

- Staff movement: Planning for staff accessibility to ensure smooth operations.

2. Understanding Workflow in Industrial Laundry

Workflow in industrial laundry involves the movement of items through various stages of the washing process. The layout should be designed to promote a logical flow, so items move from one process to the next with minimal handling and transport. This keeps everything running smoothly, reducing bottlenecks and downtime.

2.1. How a Well-Designed Layout Enhances Workflow

An efficient layout promotes a continuous, unhindered flow. By minimizing unnecessary movements and ensuring equipment is easy to access, you help staff maintain a steady pace throughout their tasks.

2.2. Optimizing Workflow Efficiency

To optimize workflow, the layout should:

- Align equipment according to the sequence of operations (e.g., washing machines near dryers, folding tables near storage).

- Consider the size of the laundry facility. A smaller space might need more creative solutions to maximize efficiency.

- Incorporate clear signage to prevent confusion and enhance navigation.

Reducing Movement Time

One of the best ways to improve workflow efficiency is to reduce the time workers spend moving from one area to another. For example, placing the washing area near the drying and folding sections can cut down the distance staff need to travel.

Minimizing Equipment Downtime

Proper maintenance and strategic placement of machines can reduce downtime. By ensuring that machines are easy to maintain, troubleshoot, and repair, you minimize disruptions to the laundry process.

Streamlining Staff Operations

Staff should have easy access to all areas of the laundry. Avoid bottlenecks by ensuring that there’s enough space for staff to move freely between stations, and that the equipment is designed with ergonomics in mind.

3. Factors to Consider in Industrial Laundry Design

When designing an industrial laundry, several factors need to be taken into account to ensure an optimal workflow:

3.1. Space Planning and Zoning

Zoning refers to separating the laundry space into different functional areas, such as washing, drying, folding, and storing. Each zone should be placed in a sequence that matches the operational process.

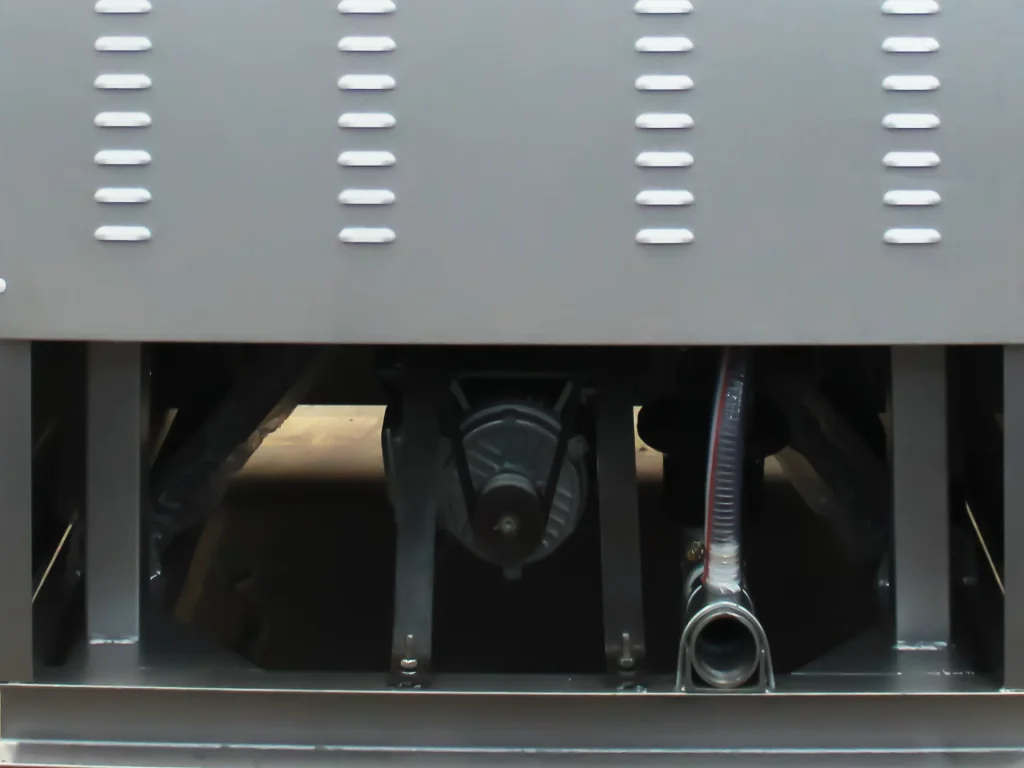

3.2. Equipment Placement

Machines should be placed in a way that minimizes movement between them. Consider the flow of laundry from one machine to the next and try to keep equipment close to each other. Also, ensure that each machine has enough space around it for maintenance and repair.

3.3. Ergonomics and Staff Safety

Designing the space with staff ergonomics in mind is crucial. The layout should reduce unnecessary lifting, bending, or reaching, which can cause strain. Additionally, safety should always be a priority—proper ventilation, non-slip floors, and clear emergency exits are essential.

3.4. Energy Efficiency and Sustainability

Energy-efficient designs help reduce costs and environmental impact. By incorporating energy-saving technologies like efficient washers and dryers or utilizing natural light, you can create a more sustainable operation.

4. The Role of Technology in Modern Laundry Layouts

Technology is transforming how industrial laundries operate. From automation to smart management systems, new tech can improve workflow, reduce energy consumption, and even boost productivity.

4.1. Automation in Laundry Operations

Automated systems can handle repetitive tasks such as folding or sorting, allowing staff to focus on more critical duties. Machines that adjust water temperature, wash time, and detergent usage based on the load type can also optimize efficiency.

4.2. Smart Systems for Workflow Management

Smart systems can track the movement of laundry items in real-time, alert managers to maintenance needs, and even forecast energy consumption. These systems offer valuable insights into optimizing your layout.

5. Common Mistakes in Industrial Laundry Layouts

Even the best designers can make mistakes. Here are a few common pitfalls to avoid when planning your industrial laundry layout:

5.1. Poor Workflow Planning

Inadequate planning of the workflow can lead to bottlenecks, delays, and overall inefficiency. Ensure the layout facilitates smooth, logical transitions between different processes.

5.2. Underestimating Equipment Needs

Choosing the wrong equipment or not accounting for future growth can lead to inefficiencies down the road. Make sure your layout is flexible enough to accommodate future expansions or changes in your equipment needs.

5.3. Ignoring Safety Protocols

Failing to prioritize staff safety in your design can lead to accidents and injuries. Always consider proper ventilation, fire exits, and equipment maintenance in your design.

6. Case Studies of Effective Laundry Designs

Let’s look at a few real-world examples of laundry layouts that have been optimized for efficiency:

6.1. Real-World Examples of Optimized Layouts

One industrial laundry in California improved its workflow by reconfiguring its layout to ensure that washing machines were closer to the dryers. This change reduced the time spent moving laundry and resulted in a 20% increase in throughput.

7. Conclusion: Key Takeaways for a Successful Laundry Layout

An optimal laundry layout is about more than just equipment—it’s about designing a system that enhances workflow, reduces downtime, and maximizes efficiency. By focusing on key factors like zoning, equipment placement, and technology, you can improve your operation’s performance and safety. The right design leads to improved productivity and a more sustainable, profitable laundry business.

8. FAQs

How do I design an efficient industrial laundry layout?

Start by zoning the space for different laundry stages and ensure the equipment flows logically from one area to the next. Plan for space around each machine for ease of maintenance.

What are the most common mistakes in laundry design?

Common mistakes include poor workflow planning, underestimating equipment needs, and neglecting safety considerations.

How can I reduce energy consumption in my laundry?

Use energy-efficient machines, implement smart systems to monitor energy use, and consider natural lighting to reduce electricity consumption.

Why is automation important in industrial laundry?

Automation helps improve efficiency, reduce labor costs, and enhance consistency in processes like folding and sorting.

What role does ergonomics play in laundry layout design?

Ergonomics ensures that staff can work without strain, reducing the risk of injury and improving overall productivity.

Here are some other articles that we think might interest you:

Environmental Impact of Industrial Laundry